Application field of metal foam

2015-05-07

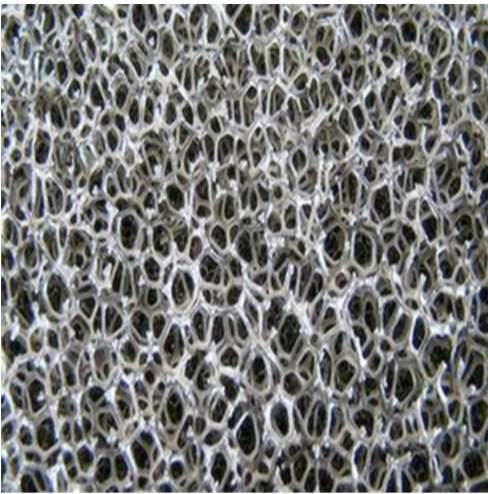

Application field of metal foam Metal foam is a product of modern structural material research. It has been widely used in aerospace, petrochemical, environmental protection and other fields now due to its excellent sound insulation, heat insulation, gas permeability and excellent impact energy absorption performance. A car made of a foam material not only enhances the safety of the collision buffer, but also effectively reduces the weight of the car and improves fuel efficiency. The bullet-proof vests developed by the composite metal foam can be easily resisted by the special ceramic slabs, and the armor-piercing bullets with a speed of more than 3,000 kilometers per hour can be easily used. The armor of some warships is even made of foam metal materials, so the application prospect of the foam metal is self-evident. Metal Foam are currently widely used in the main types of nickel foam, copper foam, aluminum foam, Titanium Foam, Graphene Foam,Etc. They are mainly used to manufacture automobile bumpers, electromagnetic shields, fluid filters, electromechanical shock absorbers, and the like. Metal foam as an emerging material, its development space can be said to be limitless, so the research and testing of foam metal is particularly important. the mechanical properties of foam metal are the key to the performance of foam metal materials.

continue reading

Daisy@foam-material.com

Daisy@foam-material.com