Wire Rod Coater: Enhancing Material Properties and Performance

● Introduction

Wire rod coating is a crucial process in various industries, enhancing the properties and performance of wire rods used in construction, electronics, automotive, and other sectors. The coating process involves applying a protective or functional layer to wire rods, improving their durability, corrosion resistance, electrical conductivity, and aesthetic appeal. A lab coater is a specialized machine designed to apply these coatings efficiently and uniformly.

● Importance of Wire Rod Coating

1. **Corrosion Resistance**: Coating wire rods with materials such as zinc, aluminum, or polymeric substances protects them from corrosion, significantly extending their lifespan, especially in harsh environments.

2. **Electrical Insulation and Conductivity**: Coatings can enhance the electrical properties of wire rods, making them suitable for use in electrical and electronic applications where specific conductivity or insulation is required.

3. **Mechanical Protection**: Coatings provide an additional layer of protection against mechanical damage, such as abrasion and wear, improving the overall durability of the wire rods.

4. **Aesthetic Improvement**: Coatings can also enhance the visual appearance of wire rods, making them more suitable for consumer products and applications where appearance matters.

● Types of Coatings

1. **Metallic Coatings**:

- **Galvanizing**: Applying a zinc coating to steel wire rods to protect them from rust and corrosion.

- **Aluminizing**: Coating wire rods with aluminum to provide a corrosion-resistant and heat-resistant layer.

- **Copper Plating**: Enhancing the electrical conductivity and corrosion resistance of wire rods.

2. **Polymeric Coatings**:

- **PVC Coating**: Provides excellent insulation, weather resistance, and flexibility, making it suitable for electrical wires and outdoor applications.

- **Polyethylene Coating**: Used for its chemical resistance, low friction, and durability.

3. **Paint and Varnish Coatings**:

- **Protective Paints**: Offer corrosion resistance, UV protection, and aesthetic enhancement.

- **Varnishes**: Provide a protective, glossy finish that enhances the appearance and longevity of the wire rods.

● Wire Rod Coating Techniques

1. **Hot-Dip Coating**:

- Involves dipping the wire rod into a molten bath of coating material (e.g., zinc for galvanizing).

- Provides a thick, durable coating but may require post-coating processes like cooling and finishing.

2. **Electroplating**:

- Uses an electrical current to deposit a metal coating (e.g., copper) onto the wire rod from a solution containing the coating material.

- Allows for precise control of coating thickness and uniformity.

3. **Powder Coating**:

- Involves applying a dry powder (e.g., polyester, epoxy) to the wire rod, which is then cured under heat to form a solid, protective layer.

- Provides a uniform, durable finish with excellent resistance to wear and corrosion.

4. **Extrusion Coating**:

- Involves extruding a molten polymer (e.g., PVC, polyethylene) around the wire rod to form a continuous, insulating layer.

- Commonly used for electrical cables and wires.

● Components of a Wire Rod Coater

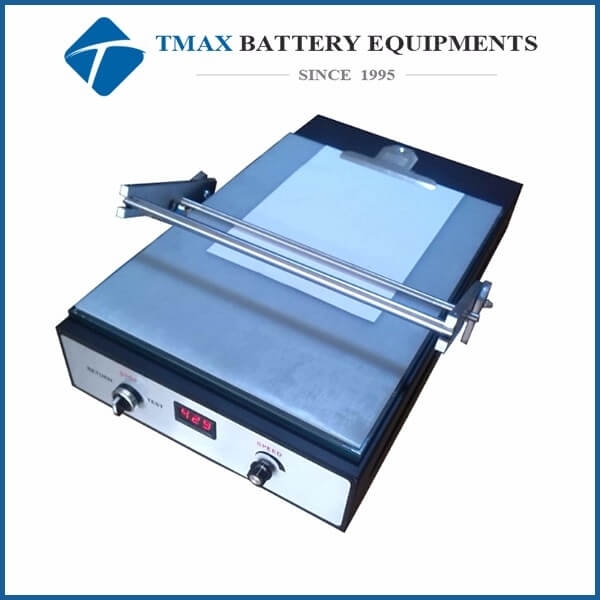

1. **Coating Application Unit**:

- The core component where the coating material is applied to the wire rod.

- May include dip tanks, electroplating baths, powder spray booths, or extrusion heads, depending on the coating technique.

2. **Pre-Treatment Section**:

- Prepares the wire rod surface by cleaning, degreasing, and sometimes applying a primer to ensure good adhesion of the coating.

3. **Heating and Curing Section**:

- Involves ovens or furnaces for curing powder coatings or drying paints and varnishes.

- Ensures the coating material adheres properly and achieves its final properties.

4. **Cooling and Finishing Section**:

- Cools down the coated wire rod to ambient temperature.

- May include additional finishing steps like polishing or applying a secondary protective layer.

5. **Control System**:

- Manages the entire coating process, ensuring consistent application, temperature control, and quality monitoring.

- May include computerized control panels and sensors to automate and optimize the coating process.

● Applications

1. **Construction Industry**: Coated wire rods are used in reinforced concrete, fencing, and as binding wires due to their enhanced corrosion resistance and durability.

2. **Electrical and Electronics**: Used in wiring, cables, and components where specific electrical properties and insulation are required.

3. **Automotive Industry**: Wire rods with protective coatings are used in various vehicle components, offering resistance to corrosion and mechanical wear.

4. **Consumer Goods**: Coated wire rods are used in products like clothes hangers, garden tools, and household appliances, where both aesthetics and protection are important.

● Conclusion

Wire rod coating is a vital process that significantly enhances the properties and performance of wire rods used in a wide range of applications. The development and optimization of wire rod coaters and coating techniques continue to evolve, driven by the need for better durability, efficiency, and environmental sustainability. As industries demand higher performance and longer-lasting materials, the role of advanced wire rod coating technologies becomes increasingly important.